link mounted cranes are essential equipment in various industries, including construction, transportation, and logistics. These powerful machines provide the ability to lift and transport heavy loads with precision and efficiency. However, operating a truck mounted crane comes with inherent risks, making safety a top priority for operators and workers on job sites. In this comprehensive guide, we will explore the various safety features and best practices that ensure the safe operation of truck mounted cranes.

1. Understanding Truck Mounted Cranes

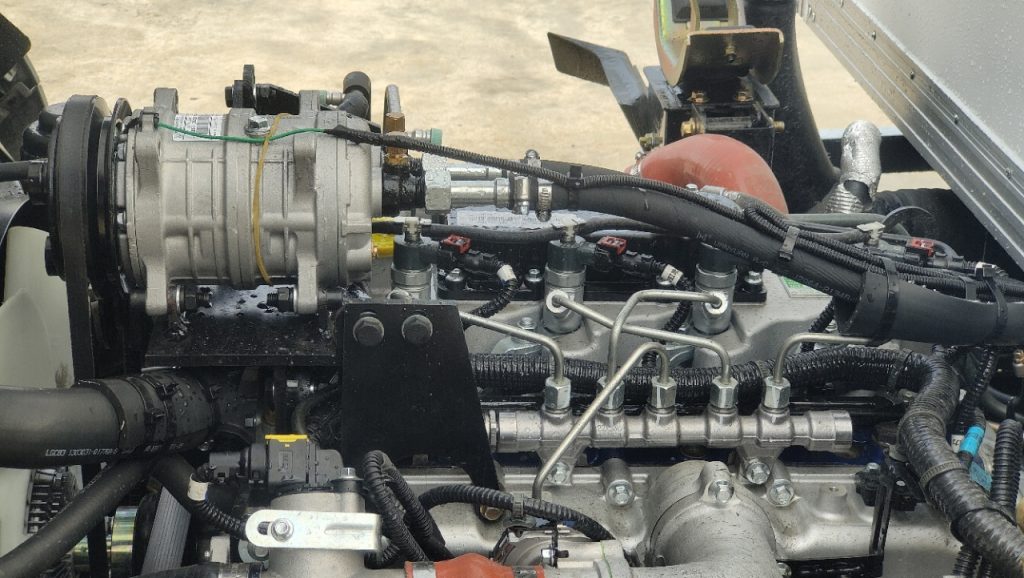

Before delving into safety features, it is crucial to understand the basic components and operation of truck mounted cranes. These cranes consist of a crane mounted on a truck chassis, providing mobility and versatility on job sites. The crane is typically controlled by a hydraulic system that enables lifting, lowering, and transporting heavy loads with ease.

The key components of a truck mounted crane include the boom, jib, counterweights, outriggers, and controls. The boom is the primary lifting arm of the crane, while the jib provides additional reach and flexibility. Counterweights are used to balance the crane when lifting heavy loads, and outriggers are deployed to stabilize the crane during operation. The controls, located in the operator's cab, allow for precise manipulation of the crane's movements.

2. Safety Features of Truck Mounted Cranes

To ensure the safety of operators, workers, and bystanders, truck mounted cranes are equipped with various safety features that mitigate risks and prevent accidents. These safety features are designed to enhance operational efficiency while reducing the likelihood of incidents on job sites. Let's explore some of the key safety features of truck mounted cranes:

a. Load Moment Indicator (LMI): The Load Moment Indicator is a crucial safety feature that monitors the crane's load capacity and operating limits in real-time. It provides visual and audible warnings to the operator when the crane approaches or exceeds its safe working load, preventing overloading and tip-overs.

b. Anti-Two Block System: The anti-two block system is designed to prevent the crane's hook block from contacting the boom tip, which can lead to catastrophic failure. This safety feature automatically stops the crane's hoist function when the two blocks come into close proximity, protecting the crane from damage and ensuring safe operation.

c. Outrigger Monitoring System: Outriggers are essential for stabilizing the crane during lifting operations. The outrigger monitoring system alerts the operator if the outriggers are not fully deployed or if the crane is operating on uneven ground, reducing the risk of tip-overs and ensuring stability.

d. Boom Angle Indicator: The boom angle indicator provides the operator with real-time feedback on the angle of the boom, enabling precise positioning and safe operation. By monitoring the boom angle, operators can avoid overloading the crane and maintain stability during lifting operations.

e. Emergency Stop System: In the event of an emergency or malfunction, the crane is equipped with an emergency stop system that immediately halts all crane functions. This feature allows operators to quickly stop the crane's movements and prevent accidents or injuries on the job site.

f. Overload Protection System: The overload protection system is designed to prevent the crane from lifting loads that exceed its rated capacity. When the crane approaches its maximum load capacity, the system triggers an alarm and stops the lifting operation, ensuring the safety of both the operator and the equipment.

g. Automatic Hook Positioning: Automatic hook positioning systems help operators accurately position the hook over the load, reducing the risk of swinging or unstable loads. This feature enhances operator control and precision during lifting operations, improving overall safety and efficiency.

h. Wireless Remote Control: Some truck mounted cranes are equipped with wireless remote control systems that allow operators to control the crane from a safe distance. This feature enhances operator visibility and flexibility, reducing the risk of accidents and improving overall job site safety.

3. Best Practices for Safe Operation

In addition to the safety features built into truck mounted cranes, operators must follow best practices to ensure safe operation and prevent accidents. Adhering to established safety guidelines and procedures is essential for protecting personnel, equipment, and the surrounding environment. Here are some best practices for safe operation of truck mounted cranes:

a. Operator Training: Operators should undergo comprehensive training on the safe operation of truck mounted cranes, including proper use of controls, load handling procedures, and emergency protocols. Training programs should cover crane operation, maintenance, and safety practices to ensure operators are competent and knowledgeable.

b. Pre-Operation Inspection: Before each use, operators should conduct a thorough pre-operation inspection of the crane to check for any defects, malfunctions, or damage. Inspecting critical components such as the boom, outriggers, controls, and safety systems is essential for identifying potential hazards and ensuring the crane is in safe working condition.

c. Load Capacity Assessment: Operators must accurately assess the weight of the load to be lifted and ensure it does not exceed the crane's rated capacity. Overloading the crane can lead to structural failure, tip-overs, and accidents, highlighting the importance of proper load calculations and weight distribution.

d. Proper Positioning: When setting up the crane for operation, operators must ensure the outriggers are fully deployed on stable ground to provide adequate support and stability. Proper positioning of the crane is essential for preventing tip-overs, structural damage, and accidents during lifting operations.

e. Clear Communication: Effective communication between the crane operator and ground personnel is crucial for safe operation. Signal persons should use standardized hand signals or radio communication to relay instructions to the operator, ensuring everyone is aware of the lifting activities taking place.

f. Avoiding Obstacles: Operators should be vigilant and avoid operating the crane near power lines, obstacles, or congested areas that could pose a hazard. Maintaining a safe distance from overhead obstructions and following clearance guidelines is essential for preventing accidents and ensuring a safe work environment.

g. Weather Conditions: Operators should be mindful of weather conditions that could impact crane operation, such as high winds, rain, or extreme temperatures. Operating a crane in adverse weather conditions can compromise stability and safety, necessitating the suspension of lifting activities until conditions improve.

h. Regular Maintenance: Proper maintenance and inspection of the crane are essential for ensuring safe operation and prolonging the equipment's lifespan. Routine checks of hydraulic systems, electrical components, structural integrity, and safety features should be conducted to identify and address any issues promptly.

4. Conclusion

Truck mounted cranes are valuable assets in various industries, providing efficient lifting and transport capabilities on job sites. However, the safe operation of these powerful machines requires adherence to strict safety protocols, the utilization of advanced safety features, and the implementation of best practices by trained operators. By understanding the key safety features of truck mounted cranes, following established guidelines, and prioritizing safety in all operations, companies can mitigate risks, prevent accidents, and create a safer work environment for all personnel involved.

In conclusion, ensuring safety in the operation of truck mounted cranes is paramount to protecting lives, preventing injuries, and preserving equipment. By investing in robust safety features, providing comprehensive training to operators, and implementing best practices for safe operation, companies can foster a culture of safety and excellence in crane operations. Truck mounted cranes will continue to play a vital role in the construction and logistics industries, and prioritizing safety will be key to maximizing their potential while minimizing risks.